Over forty years of experience in molds, component parts, gages and fixtures

Holbrook Tool & Molding Inc.

Mold repair &

troubleshooting

Our design department offers two full time designers and three CAD systems.

Holbrook Tool & Molding Inc.

CNC machining

& CNC turning

We have five CNC machining centers and a CNC turning center.

Holbrook Tool & Molding Inc.

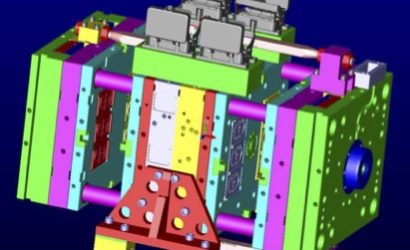

Mold Construction and Custom Molding

ISO 9001:2015

ISO 13485:2016

We have ISO 9001:2015 and ISO 13485:2016 certifications for the production of plastic parts.

3600 sq. ft. Class

100,000 Cleanroom

Our climate controlled facility includes design, quality control, manufacturing and cleanroom.

Holbrook Tool & Molding Inc.

Holbrook Tool & Molding - Injection Mold Tooling & Custom Molding

With approximately 35 full-time employees located in a modern, climate controlled 22,800 sq. ft. facility that includes office, design, quality control, manufacturing and cleanroom molding areas, Holbrook Tool & Molding is here to serve you.

Holbrook Toool has more than forty years experience in molds, component parts, gages and fixtures. We specialize in mold construction and custom molding. We also offer all types of grinding, including form grinding, carbide and centerless grinding. We also have five CNC machining centers and a CNC turning center which gives us the opportunity to offer both CNC machining and CNC turning capabilities. We have ten fully capable CNC EDM’s.

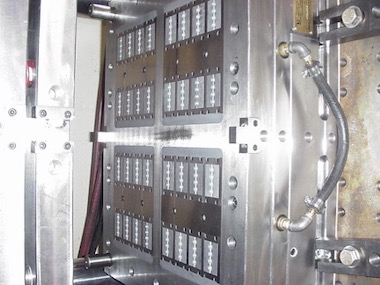

We possess the ability to design/build/run production/prototype molds, inserted overmolds and production molds. Recently we have excelled in the medical, consumer product and electronic fastener fields. Our capabilities include single or multi cavity tools with conventional runners or hot manifold systems.

Our Design Department currently has one seat of CREO and one seat of KeyCreator. This software gives us the ability to design molds using the customers’ part print and or electronic files. We also have four CAM stations that support Mastercam.

When the manufacturing processes are completed, we have a full tooling inspection program. We also have ISO 9001:2015 and ISO 13485:2016 certifications for the manufacture and supply of plastic components.

-

Machining

-

Grinding

-

EDM

-

Molding

ISO 9001:2015 and ISO 13485:2016 certifications for the production of plastic parts.

Quality & Experience

At Holbrook Tool & Molding, Inc we offer a high level of product quality and customer service. With more than fifty years combined experience in molds, component parts, gages and fixtures, we have a keen understanding of the industry and our customers' requirements.

Innovation & Value

We go the extra mile to provide you with on time delivery, value, quality and technical support. With our innovation and expertise, we provide the solutions to your business needs. Our team of craftsmen becomes your partners in meeting the tooling and molding demands of your business.

Contact Holbrook Tool & Molding

Call (814) 336-4113 to talk to an engineer about your next project.